Description

The iClean Automatic Lubrication Maintenance Unit is a cutting-edge solution designed to streamline and enhance machinery lubrication processes. This innovative device is engineered to deliver precise and timely lubrication to critical components, ensuring optimal performance, longevity, and reduced downtime for industrial equipment.

iClean Automatic Lubrication Maintenance Unit

Key Features:

- Automatic Lubrication:

Continuous and automated lubrication of machinery parts.

Eliminates the need for manual lubrication, reducing human error and ensuring consistent coverage.

- Adjustable Lubrication Intervals:

Customizable lubrication intervals to match specific machinery requirements.

Flexibility to adapt to different operating conditions and usage patterns.

- Smart Monitoring System:

Integrated sensors for real-time monitoring of lubrication levels.

Alerts and notifications for timely maintenance, preventing equipment wear and tear.

- Versatile Compatibility:

Compatible with a wide range of industrial machinery and equipment.

Adaptable to diverse lubrication needs across various industries.

- Weather-Resistant Design:

Built to withstand harsh environmental conditions.

Ensures reliable operation in both indoor and outdoor settings.

- User-Friendly Interface:

Intuitive control panel for easy setup and monitoring.

Simplified programming for lubrication intervals and volume adjustments.

- Energy-Efficient Operation:

Optimized lubrication delivery to minimize waste and reduce operational costs.

Energy-efficient design for sustainable and cost-effective maintenance.

- Compact and Space-Saving:

Streamlined design for easy integration into existing machinery setups.

Space-saving form factor without compromising functionality.

- Long-lasting Battery Life:

Efficient power management for extended battery life.

Reliable performance without frequent battery replacements.

- Enhanced Equipment Lifespan:

Consistent lubrication leads to reduced friction and wear on critical components.

Prolongs the lifespan of machinery, minimizing the need for costly repairs.

Click Here to View Other Maintenance Products

Downloads

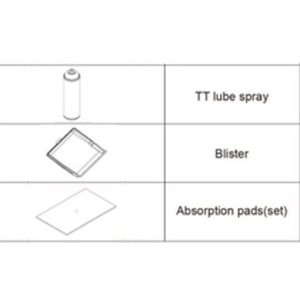

iClean Automatic Lubrication Unit

iClean Instructions for Use